User’s Manual for models with Johnson Controls A419

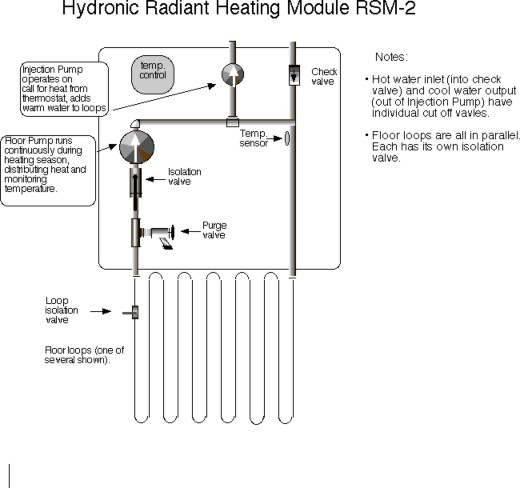

The RSM circulates and controls warm water for radiant heating. It would typically be used to heat a concrete slab via embedded pipes, but can feed pipes in a poured wall, attached to a wood floor, or in a greenhouse plant bed as well. The module provides precise radiant loop temperature control (±1°F) by constantly monitoring return water temperature and, upon demand, injecting heated water from any of a variety of sources: water heater, boiler, or solar storage tank.

The module includes a continuous circulation pump, an injection pump, maintenance valves, and a temperature control (the “set point control”, or thermostat).

Quick Information List (the essentials)

- How do I adjust the temperature? The radiant loop temperature is maintained by the Set Point Control, the Johnson Controls A419. The display normally shows current sensor (slab) temperature. To adjust the desired temperature (the set point), press and hold “Menu” until the display flashes “SP”. Press Menu again to display the existing set point. Press up or down arrows to change the set point. Press Menu again to save the new setting.

Most people find one setting works for the entire heating season. Since radiant heat is a gentle process, if you change the temperature setting allow several hours to feel the difference.

The temperature of the hot water (both for domestic use and to supply the RSM) is set by the water heater, not the Set Point Control.

- When should I turn the heating system on and off? The system should remain on during the heating season. If the building is to be unoccupied you may wish to turn the system off if there is no danger of freezing, or you can just

turn the A419 thermostat down to maintain a safe temperature for house plants and/or plumbing pipes.

Outside the heating season we recommend the system be turned on for five minutes at least once per week with the thermostat turned up above 85°. Running the pumps occasionally like this keeps them freed from deposits and also flushes fresh water into the floor loops. A timer can be installed to do this automatically.

At the beginning of the heating season, we strongly recommend flushing the floor loops with fresh water. See the “Maintenance” section, below, for instructions.

- How do I tell if the RSM is working? When the power is on the A419 display should be active and the circulation pump (the larger of the two pumps) should be running. The pump makes a slight hum and, after running a few minutes, is normally warm to the touch. The display shows current floor water temperature. When the thermostat senses that the floor needs more heat it will click its relay (“Output Relay Status Indicator” LED will light) and turn on the injection pump. The displayed temperature will cycle up and back as hot water is injected into the floor mix.

Description of Operation

When the RSM is turned on the circulation pump and thermostat are energized. In a typical home installation the unit would remain on throughout the heating season. While the main function of the RSM is to add heat to the slab, this continual circulation helps distribute heat gained through passive means — making the whole slab part of the passive solar mass — and allows continuous slab temperature monitoring.

This model of RSM uses a Johnson Controls A419 set point control (thermostat). The thermostat is set by the user dependent on comfort requirements in the dwelling. A typical setting would be between 75 and 89°F. Since this is slab temperature and not air temperature, the setting usually is higher than what you are used to for an air thermostat, and usually does not need to be changed once a comfort level is determined. The thermostat compares a temperature sensor located on the radiant loop water pipe or embedded in the slab with the stored set point value – the desired temperature. If the slab water is cooler than the set point, heat input is called for by passing 120vAC to the injection pump, which begins mixing hot water in with the cooler water circulating through the floor loops. Since normally the hot input water would be above the high limit set internally by the thermostat (this setting is called the “differential” in the Johnson Controls literature), the addition of this heat will soon bring the temperature up and the injector pump will shut off.

During this period, the heat is circulated through the slab. In a few seconds the sensor will cool down and the injector pump will again be turned on. This cycling of the injector pump will continue until the whole radiant area (slab, wooden floor, or walls) has reached the temperature setting. The period of this cycle will depend on several factors, the main ones being temperature of the inlet water and circulation flow rate.

A note regarding outdoor reset:

The A419 has the option of having a switch closure to shift the set point. The programming can control how much the set point shifts when the contact is closed. This feature can be used with an outdoor thermostat to boost the heat output when the temperature falls below a certain point, or it could be used with a remote switch to boost the heat when manually turned on.

Maintenance

Since the pumps are lubricated by the water they pump they require no maintenance, but if they sit too long without running the water can leave deposits that will prevent the pump from being able to start on its own. It will then have to be taken apart and freed up. To prevent this, we advise you to run the RSM for five minutes at least once each week during the non-heating season. An electronic timer can be installed to do this automatically.

The shutoff and purge valves are used for maintenance only and do not need to be changed in normal operation. In the event of a leak in the floor loop pipes unplug the RSM and shut both isolation valves to and from the water heater.

If feed water pressure is lost turn off the RSM immediately to prevent damage to the pumps. Warranty is void if the module is ever operated without adequate water to cool the pumps.

Should maintenance be required for the hot water tank or hot water pipes, before draining the water heater switch off the RSM and close the ball valve that supplies hot water to the RSM. Only after water pressure is restored,

the tank is full, and air has been purged from the potable lines is it safe to open the RSM feed valve and turn the unit back on.

The whole radiant floor piping system should be flushed after any introduction of air into the hot water lines. This is accomplished, with the RSM switched off or unplugged, by attaching a hose to the purge valve and closing the isolation valve, which prevents water from being allowed to go the “short route” backwards through the circulation pump to the purge valve. Close the hot water inlet valve so only cold water will be used in the purging. Close all individual loop isolation valves except one and open the purge valve fully. As that loop is purging watch and listen for air bubbles. If none are detected for one minute, open the next floor loop valve and close the first. Continue this process for each floor loop. This will force water through each loop one at a time.

Close the purge valve and open all ball valves, then plug in the control.

Troubleshooting

|

Symptom: |

Likely Causes: |

|

1) Pumps never run. |

1a) If A419 display is not active check AC power at outlet. |

|

1b) Turn up the thermostat. This should force the output on (LED and injection pump will come on.) Note which of these things happens and call Solar Consultants. |

|

|

2) Circulation pump is running but no heat is being supplied to the house. |

2a) If the injection pump is running, feel the pipe from the water heater to that pump (NOT the pump itself) and see if it is warm. If it is not warm, then your water heating is faulty or a valve has been closed, not allowing the injection pump to circulate hot water into or cold water out of the loops. |

|

2b) If the injection pump is not running, perform the test in 1b), above. If the injection pump starts up you should be able to feel the pipe from the water heater getting warm, and then the pipe feeding the radiant loops get warm. If all this performs as it should the problem is most likely in the thermostat or its temperature sensor. |

|

|

3) Noises |

The pumps are lubricated by the water they pump. The noise should be a steady hum. Pinging or a soft “popcorn popping” indicates air in the lines; this is not a dire emergency but can reduce circulation and should be dealt with by purging before… Screeching indicates bearings shot; unplug the RSM immediately. |

Specifications

Electrical requirements (Watts @ 115vAC) typical: 100 maximum: 220 Options:

- Remote digital temperature readout (six inputs).

- Direct Current models available.

Design changes and part substitutions may be incorporated in custom or future systems.

Warranty

Parts and workmanship are warranted by Solar Consultants for one year from the installation date. Individual parts, especially tanks, pumps, and controls, are covered by additional manufacturers’ warranties. After the first year, Solar Consultants will repair or replace (at our discretion) any part still covered under a manufacturer’s full parts warranty without any labor charge.

Taco pumps have a one-year replacement/repair warranty for the electrical portion and three years for the cartridge, which contains all the moving parts. Armstrong and Wilo pumps have two-year warranties.

Johnson Controls and Ranco thermostats have a one-year warranty.

Solar Consultants is not responsible for damage or loss of service attributable to domestic water chemistry, including but not limited to hardness, acidity, or chloramine content. Warranty is void if pumps are ever allowed to run with less than 2 p.s.i. fluid pressure.

Send Us a Message

Contact Info

Fred Stewart

Licensed plumber and solar thermal system designer

Tom Willis

Licensed plumber and NABCEP-certified system designer

Richard Copsey

Installer/technician